Ended up bonded parts can be found in basically any kind of type of steel product that you can spot in day-to-day life. It's utilized in pipe-making, ductwork, automotive production, bike-making, steel-building, and much more. Unique band saws for cutting steel have set blades and feed mechanisms for even reducing. Unpleasant cut-off saws, likewise called slice saws, are similar to miter saws but have a steel-cutting rough disks. Quickly gain access to beneficial market resources currently with complete access to the digital version of The Maker en Español. Conveniently gain access to valuable market resources currently with full access to the electronic version of The Tube and Pipeline Journal.

Our Manufacture Motorists: High Quality And Consistency

These materials for sheet steel manufacture usually can be found in evaluates with 0.006 ″ to 0.75 ″ (0.015 to 1.905 centimeters) density. In this listing, you've come across prominent sorts of steel fabrication like spreading, creating, steel marking, reducing, extrusion, and welding. As pointed out before, these methods are made use of for crafting different steel parts that are made use of in a range of applications. They're additionally perfect for tailored components that can match the preferences of the end-user. Metal producers usually work with a series of basic materials that might include different types of metal such as plate steel, broadened steel, welding cables and poles, and cast metal. In short, fabrication is an important action in creating any type of type of finished metal part or structure.

1.+Fastest+Growing+Companies+2024%3A+SSE+Steel+Fabrication+increases+revenue+193%25+year-over-year - New Orleans CityBusiness

1.+Fastest+Growing+Companies+2024%3A+SSE+Steel+Fabrication+increases+revenue+193%25+year-over-year.

Posted: Tue, 07 May 2024 19:37:10 GMT [source]

Commercial Paint

The health issue arising from rough blasting directly relates to the products utilized in the process. The dusts from the blasting product as well as the blasted object can be highly poisonous if breathed in. OSHA has a number of guidelines in place to shield the wellness and well-being of welders and cutters. Besides personal safety tools, OSHA recommends engineered controls that collect dirt, smoke and fume at resource.

Aluminum:

The ability of these firms to make modern financial investments that enable them to keep a variable output is the essential to maintaining customer diversification. Metal fabrication sector has broad applications across a terrific several sectors and consumer products. Requirement resources made use of consist of plate steel, fittings, spreadings, created and increased steel, sectional metal, flat steel, and welding wire.

The factory analyze the schematic, calculate the cost of manufacturing and reply with both expense and preparation. Humans have actually been extracting and machining metal for the previous 10 millennia, as shown by a copper pendant excavators discovered in northern Iraq that dates back to about 9,000 BCE. Manufacture stores as we know them today started to exist around the Industrial Change, when sheet metal was in much greater need than before. The invention of the hydraulic press, which enabled makers to use unprecedented pressures to items of steel, changed the steel fabrication industry.

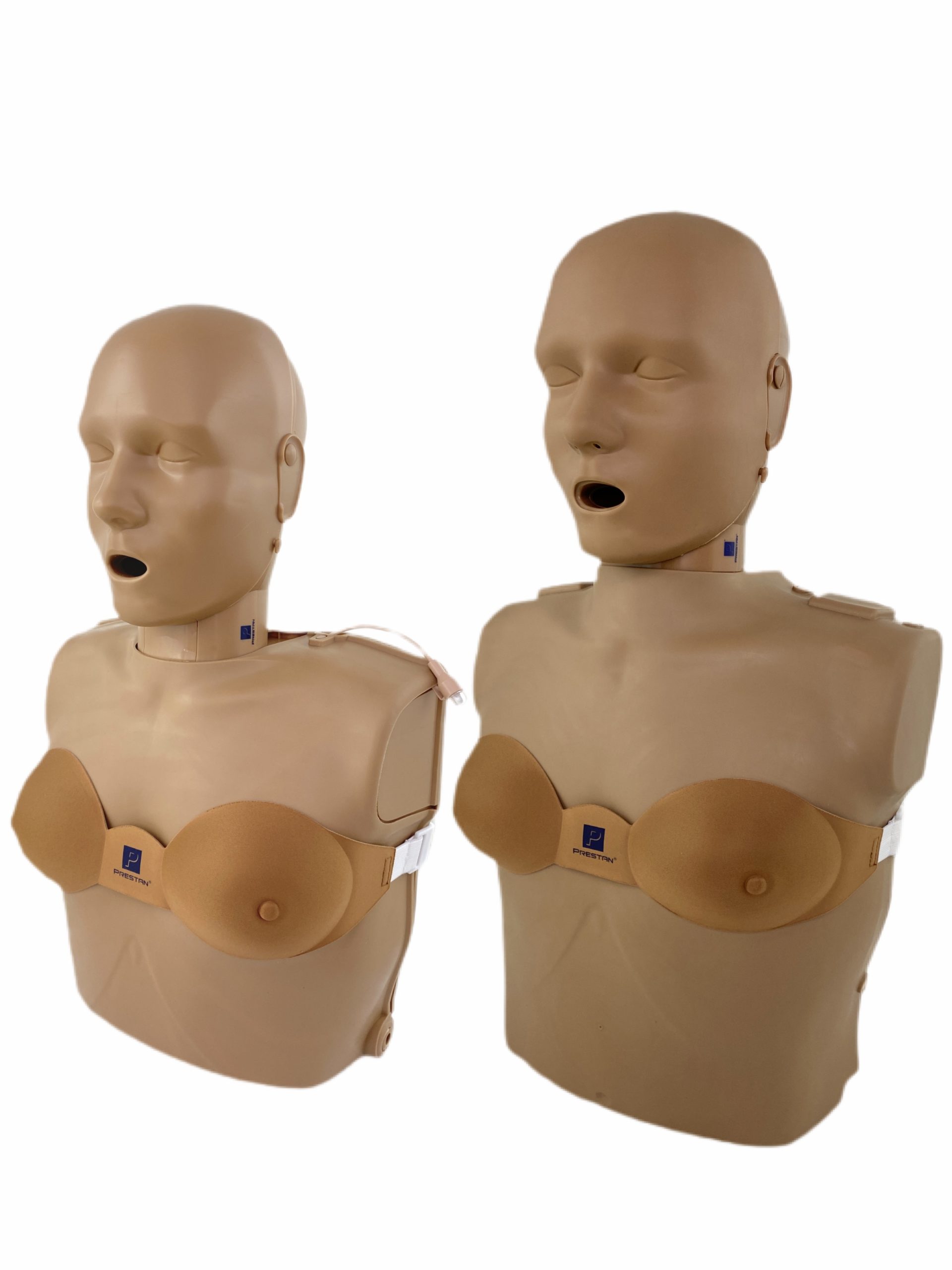

Because architectural steel is carbon steel, it contains up to 2.1% carbon by weight. High-strength and low-ductility materials are created when the carbon content of steel is raised. The needed carbon quantity or material will rely on just how the steel will be cpr training manikins used. The safety and quality requirements for producing structural steel differ by local and national requirements.

As with other making procedures, both human labor and automation are commonly made use of. A produced item might be called a fabrication, and shops concentrating on this type of work are called great stores. Steel fabrication is the process of structure devices and frameworks from raw metal products. The procedure consists of cutting, burning, welding, machining, developing, and assembly to produce the end product.

Machining is a subtractive shaping procedure that gets rid of unwanted material to produce a form. Casting is extensively accepted as the best procedure for mass-produced products where the exact same mold can be used over and over again with minimal difference in the last result. MIG, metal inert gas welding, utilizes a mechanism featuring a solid cord electrode that forms an arc in between this electrode and the product being worked, and the components are after that merged with each other. We take every action possible to guarantee the lowest cost with the finest.

Additionally, this is an outstanding material for welding as a result of the product's convenience of flexing. For that reason, stainless-steel is often utilized in applications needing deterioration resistance. Milling gets rid of extra material from a raw steel element making use of specialized multi-point cutting tools. This procedure can be accomplished manually or with the help of a CNC milling device. Milling, as a whole, is a lot more regularly utilized as a secondary steel fabrication procedure. This action concentrates on validating if all style specifications are satisfied during the metal item fabrication.

Easily accessibility valuable industry sources now with complete access to the electronic edition of The Welder. Easily accessibility beneficial industry resources currently with complete access to the digital version of The Producer. With numerous presses and bending equipment and a wide range of tooling we can flex almost any type of component and account. Spray paint also has harmful metals and chemicals that pose extra health and wellness worries when inhaled.